|

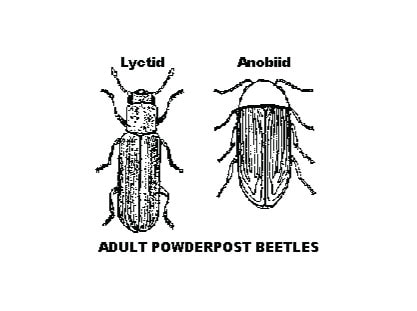

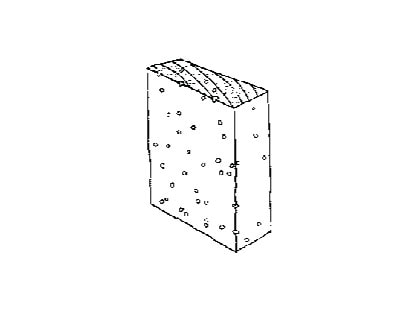

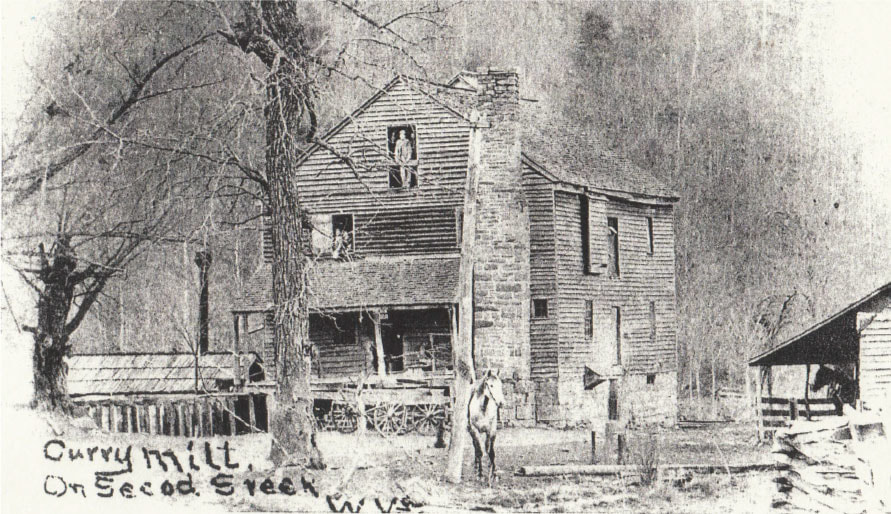

By Anna, Lynn Stasick, Statewide Field Services Representative Note: Much of the information contained in this document was provided by and courtesy of Dr. Michael F. Potter, Extension Entomologist at the University of Kentucky College of Agriculture. PAWV thanks him greatly for his time and effort. In the past fifteen to twenty years, hoteliers have experienced a growing problem with bedbug infestations in even some of the finest hotels nationwide. In response, new technology and methods to employ them have been developed to combat the problem. First, bedbug sniffing dogs are sent in to identify what rooms are infested. Once the location of the infested rooms is established, dry heat units are brought in to heat the room to a fairly high temperature, and then maintaining that temperature for up to an hour, thus exterminating the insects. The following information discusses an infestation of a different species of insect and the problems using poisons in a historic flour mill. PAWV had been contacted by the mill owner to discuss the problem. In response, the author visited the site to observe the situation firsthand. Since then, she has been modifying the bedbug technology to suit the problems the mill owners are facing with the Powderpost beetle. To understand the situation, please read further. “Powderpost beetle” is a name used to describe several species of small (1/8-3/4 inches long), wood-boring insects that reduce wood to a fine, flour-like powder. Damage is done by the larvae as they create narrow, meandering tunnels in wood as they feed. Infestations are discovered after noticing small, round “shot holes” in the wood surface. These are exit holes where adult beetles have chewed out of the wood after completing their development. Newly-emerged adults mate and lay eggs on or below the surface of bare (unfinished) wood. The eggs hatch into tiny larvae which bore into the wood, emerging as adults 1-5 years later, usually during April – July. Damage is more likely seen than the beetles themselves, since the adults are short-lived and are active mainly at night. The two most common and destructive families of powderpost beetle in Appalachia are the Lyctidae and Anobiidae. Lyctid powderpost beetles attack only wood products manufactured from hardwoods, such as oak, ash, walnut, and hickory. Consequently, infestations are most often found in wood paneling, molding, window and door frames, plywood, hardwood floors, and furniture. Lyctids rarely infest wood older than five years. Anobiid powderpost beetles may attack both hardwoods and softwoods, which means that infestations may be found in all the same places as Lyctid beetles, as well as in structural timbers (beams, sills, joists, studs, subflooring, etc). Maple, beech, poplar, and pine are especially susceptible to attack. The Lyctid and Anobiid powderpost beetles both chew small, circular emergence holes in the surface of wood. Anobiids prefer to infest wood that is damp; therefore, infestations usually begin in moist, poorly-ventilated areas such as crawl spaces, basements, garages, and utility sheds. Holes made by Lyctid beetles are about the diameter of a pinhead, whereas exit holes made by Anobiids are slightly larger. One way to differentiate holes of the two species is to insert a “click-type” (refillable) ball-point pen into the exit hole; only the tip of the ball will fit through a Lyctid beetle emergence hole. If the hole was made by an Anobiid, the tip of the pen will enter partway up the angled face of the point. Another way to differentiate the two species is from the consistency of the powder (frass) that sifts out of the exit holes. Lyctid frass is extremely fine and feels like talc when rubbed between the fingers. Anobiid frass is also powder-like, but it feels gritty. Treatments: A number of insecticides are labeled for the surface treatment of bare, exposed wood. However, these products are contraindicated in many situations, as they are poisons. They should not be used where there is the danger of polluting rivers and streams, and they cannot be used where food processing occurs – such as at the historic gristmill discussed near the end of this article. A safer option to utilize is borax, also known as sodium borate, sodium tetraborate, or disodium tetraborate. It is an important boron compound, a mineral, and a salt of boric acid. Powdered borax is white, consisting of soft colorless crystals that dissolve easily in water. Borax has a wide variety of uses. It is a component of many detergents, cosmetics, and enamel glazes. It is also used to make buffer solutions in biochemistry, as a fire retardant, as an anti-fungal compound, in the manufacture of fiberglass, as a flux in metallurgy, in making neutron-capture shields for radioactive sources, as a texturing agent in cooking, and as a precursor for other boron compounds. Most crucially for preservation purposes, borax – along with its inverse, boric acid – is useful as an insecticide. I bolded the fact that borates are used as both an insecticide and a thickening agent in cooking to indicate that borax is quite safe. It is always important, however, to read and follow the instructions closely on any product container. The two borate formulations currently registered for residual surface treatment of wood are Bora-Care® and Tim-Bor®. These products remain effective for as long as 40 years. Both products are available through professional pest control operators. Individuals wishing to perform the application themselves can, with some effort, obtain Bora-Care® and Tim-Bor® through chemical distributors and lumber companies. Borates are also available online. One of the drawbacks in using borates however is that they only work on the surface, but Powderpost beetles bore to a depth of about ¼ inch, making them out of the reach of the borates. Therefore, borate applications should largely be used as a preventative measure. For example, perhaps a beam had previously been attacked, but for one reason or another, the beetles are now gone. This would be the ideal time to treat the beam with borates. As mentioned in the opening paragraphs, new and inventive ways to rid an area infested with bedbugs have arisen in the last decade and a half. Bedbugs die when temperatures reach somewhere between 111-113 degrees Fahrenheit. Nearly all insects perish as temperatures approach 120 degrees if exposed to the heat for 30 minutes to an hour. That is why some desert insects burrow deep below the sand when the day reaches its hottest. It is not unreasonable to think that since we now have the technology in place we can apply some of the same elements in the extermination of powderpost beetles as a first step, and treatment using borates as a preventative afterward. The question now is how we can apply the lessons learned from the bedbug research to various preservation uses involving the powderpost beetle. In an effort to explain, Reed’s Mill will be the example. It was built on Second Creek, straddling the Raleigh and Monroe County, West Virginia lines, circa 1791 and has been in continuous operation since. This fact is relevant, since the original “tub mills” and oaken crane arms are still present and in use.

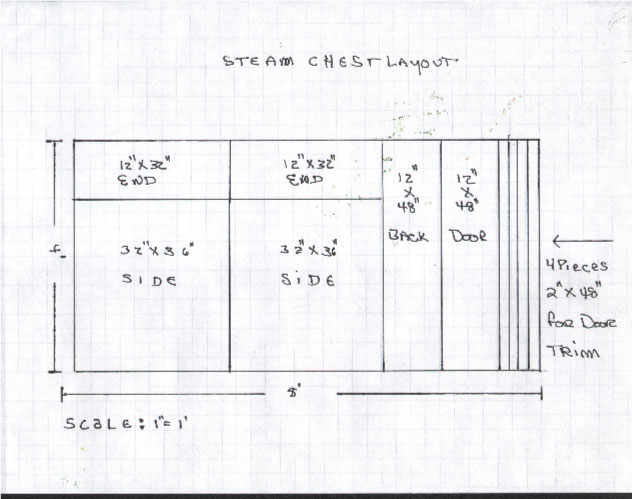

Historic photo of Reeds Mill The day the author visited, a close inspection revealed that a powderpost beetle infestation exists in both the wooden tub, which houses the bed and mill stones, and the crane, which is used to remove the mill stones. The tub mill and the crane sit in a huge, very drafty room with another floor above it and a wet basement below. Therefore, it would be impossible for the entire area to reach the temperatures needed for beetle extermination without the infested items being contained in some manner or another. The answer lies in the use of two materials easily purchased at any lumberyard or big-box hardware store. One is a pressed insulation board clad in aluminum. It comes in 4’x 8’ sheets and in varying thicknesses. A major brand name for it is R-Max, but there are others. The second material is an aluminum tape with paper backing. Together, these materials can be used to construct a box, and seal all the edges. I have found both materials to be quite useful when constructing boxes for steaming window sashes for restoration, as well as for other uses. The plan for the gristmill is to construct a box large enough to encase the crane and the tub mill and then heat the interior atmosphere to an ambient temperature of 120 degrees Fahrenheit for the desired amount of time. The process will involve boring two small holes in inconspicuous places, one in the mill tub and one in the crane, and inserting two small thermocouples designed to read internal temperature since the wood has to reach an internal temperature of about 117 degrees to a depth of ¼” as this is where the larvae live. In addition, a thermo-sensor will be installed through the R-Max wall in order to insure that the correct temperature is both attained and maintained for the time necessary. Once the heat treatment is completed, borates will be applied to both items to prevent re-infestation. Please see photos depicting a heat treatment test box and how to construct a unit using the materials referenced above. Of course the box employed at the mill will be considerably larger than the test box example below; perhaps seven by eight by nine feet or larger. The results of the testing will be published at a later date. At that time the manufacture of the heat control panel now under construction and the heat delivery system will be discussed at length. Comments are closed.

|

News and NotesCategories

All

Archives

May 2024

Subscribe to our mailing list to receive e-news updates on historic preservation news and events in West Virginia.

|

Get Involved |

Programs |

Contact UsPreservation Alliance of West Virginia

421 Davis Avenue, #4 | Elkins, WV 26241 Email: [email protected] Phone: 304-345-6005 |

Organizational Partners:

© COPYRIGHT 2022 - PRESERVATION ALLIANCE OF WEST VIRGINIA. ALL RIGHTS RESERVED.

RSS Feed

RSS Feed